News

电商部

电商部  2025-11-18 11:57:53

2025-11-18 11:57:53 NVMe Industrial SSD: Boosting Speed for Industrial IoT

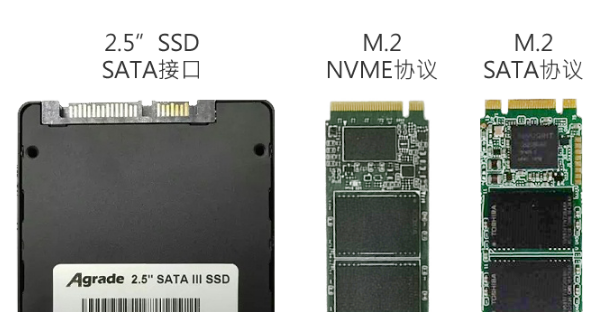

NVMe (Non-Volatile Memory Express) industrial SSDs are revolutionizing industrial storage with their ultra-fast speeds, low latency, and high efficiency — making them the ideal choice for Industrial IoT (IIoT), smart manufacturing, autonomous vehicles, and other data-intensive industrial applications. Unlike traditional SATA industrial SSDs, which are limited by the 6 Gbps SATA interface, NVMe industrial SSDs use the PCIe (Peripheral Component Interconnect Express) interface to deliver breakthrough performance, addressing the growing demand for real-time data processing in modern industries.

How NVMe Industrial SSDs Work

NVMe is a protocol designed specifically for NAND flash memory, optimizing data transfer between the SSD and the host system:

PCIe Interface: NVMe industrial SSDs use PCIe 3.0, 4.0, or 5.0 interfaces, which offer significantly higher bandwidth than SATA. PCIe 4.0 provides up to 32 Gbps per lane (128 Gbps for x4 lanes), while PCIe 5.0 doubles that to 64 Gbps per lane. This allows NVMe industrial SSDs to achieve sequential read speeds up to 7000 MB/s and write speeds up to 6000 MB/s — 5–10x faster than SATA industrial SSDs.

Parallel Processing: NVMe supports up to 64,000 I/O queues (compared to SATA’s 1 queue) and 64,000 commands per queue. This enables the SSD to process multiple data requests simultaneously, reducing latency to as low as 0.1ms (vs. 5–10ms for SATA). For IIoT applications generating thousands of small data packets per second, this parallel processing is critical for avoiding bottlenecks.

Efficient Controller Design: NVMe industrial SSDs use specialized controllers optimized for the NVMe protocol, reducing overhead and improving energy efficiency. These controllers manage data flow between the PCIe interface and NAND flash, ensuring maximum performance while minimizing power consumption — a key advantage for battery-powered IIoT devices.

NVMe-oF Support: Some high-end NVMe industrial SSDs support NVMe over Fabrics (NVMe-oF), which extends NVMe performance over network fabrics (Ethernet, InfiniBand). This allows for shared storage in industrial data centers, enabling multiple devices (e.g., robots, sensors) to access the SSD simultaneously at high speeds.

Key Benefits for Industrial Applications

NVMe industrial SSDs offer unique advantages that address the needs of modern industrial systems:

Faster Real-Time Data Processing: IIoT systems generate massive volumes of data (e.g., smart factories with 1000+ sensors) that need to be processed instantly. NVMe’s high speeds and low latency enable real-time analytics, predictive maintenance, and immediate decision-making — improving efficiency and reducing downtime. For example, a smart factory using NVMe industrial SSDs can detect equipment anomalies in milliseconds, preventing costly breakdowns.

Higher Capacity in Smaller Form Factors: NVMe industrial SSDs are available in compact form factors (M.2, U.2, E1.S) that save space in small industrial devices (e.g., drones, wearable sensors) while offering large capacities (up to 32TB). This is critical for autonomous vehicles, which need to store terabytes of sensor data in limited space.

Lower Power Consumption: NVMe industrial SSDs use less power than SATA models, especially during idle or low-load periods. This is ideal for battery-powered industrial devices (e.g., remote IoT sensors) or energy-efficient smart factories, reducing operational costs and environmental impact.

Improved Reliability for Write-Intensive Tasks: NVMe industrial SSDs often use high-quality NAND flash (SLC, MLC) and advanced features like power-loss protection (PLP) and wear-leveling. This makes them suitable for write-intensive applications (e.g., data logging in power plants) where durability is critical.

Common Use Cases for NVMe Industrial SSDs

NVMe industrial SSDs are transforming key industrial sectors:

Industrial IoT (IIoT) & Smart Manufacturing: IIoT sensors, PLCs, and robotic systems use NVMe industrial SSDs to store and process real-time data, enabling smart factories to operate more efficiently. For example, a robotic arm on an assembly line uses an NVMe SSD to store movement data, ensuring precise, low-latency control.

Autonomous Vehicles & Transportation: Autonomous cars, trucks, and drones generate terabytes of data per hour from cameras, LiDAR, and radar. NVMe industrial SSDs store this data for real-time processing (e.g., object detection) and later analysis, with fast speeds ensuring the vehicle can react quickly to changing conditions.

Medical Equipment: High-resolution medical imaging (MRI, CT scans) requires fast storage to transfer and access images instantly. NVMe industrial SSDs enable healthcare providers to view images in seconds, improving diagnosis speed and patient care.

Data Centers & Edge Computing: Industrial data centers and edge computing nodes use NVMe industrial SSDs to handle high-volume data traffic, supporting cloud-based industrial applications and reducing latency by processing data closer to the source.

How to Choose an NVMe Industrial SSD

When selecting an NVMe industrial SSD, consider:

PCIe Generation: Choose PCIe 4.0 for most industrial applications (balance of speed and cost) or PCIe 5.0 for maximum performance (e.g., autonomous vehicles).

Form Factor: M.2 for small devices, U.2 for high-capacity needs, E1.S for data centers.

NAND Type: SLC for write-intensive tasks, MLC for balanced performance, TLC for read-heavy applications.

Capacity & Speed: Match to your data volume and processing needs (e.g., 2TB with 3500 MB/s write speed for IIoT data logging).

Ruggedness: Ensure the SSD meets industrial environmental standards (temperature, shock, vibration) for your application.

NVMe industrial SSDs are the future of industrial storage, enabling faster, more efficient, and more reliable data processing for the next generation of industrial systems. As IIoT and digitization continue to grow, NVMe will become the standard for industrial SSDs, replacing SATA in most mission-critical applications.